Sheet Metal & Acrylic Fabrication and 3D Printing Services

Below are just a few of the main services we provide for creating completely custom sheet metal and acrylic products. Whatever service you need to bring your project to life, we can provide it. Visit our Free Estimate page, or give us a call at (605) 633-9116 to get started on your project.

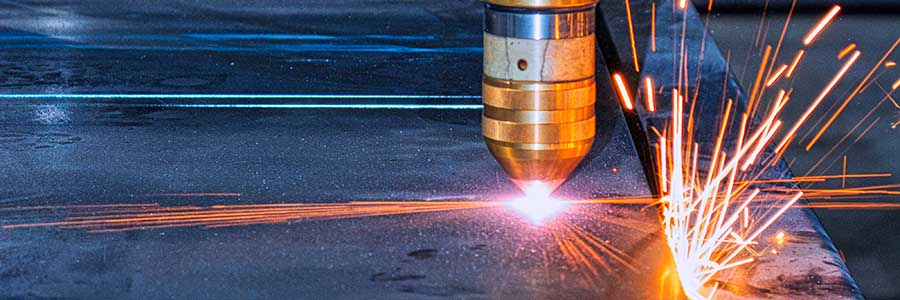

Laser Cutting

We use Laguna CO2 laser cutters to make precision cust of sheet metal and acrylic. CO2 lasers are perfect tools for engraving your favorite

designs in acrylic, thin woods, and numerous other materials.

Metal Stamping

Sheet metal stamping involves the use of a stamping press to transform sheet metal into your chosen shape or design. The die surface and the tool

use various techniques to work the metal into the desired shape or form.

Welding

Welding is another fabrication process we use to bring your project to life. Welding, simply put, is the fusing together of two items by

heat, pressure or both forming a join as the parts cool.

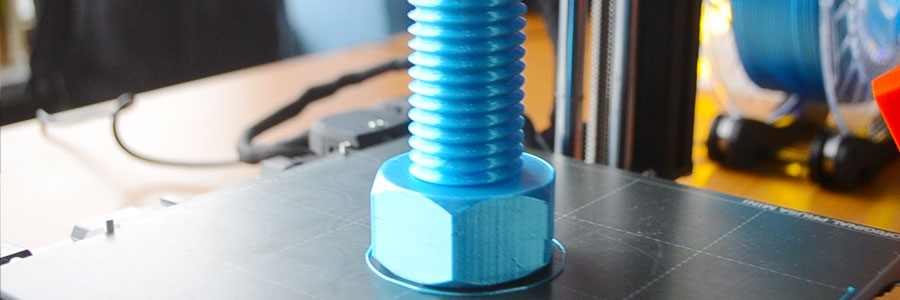

We use 3D printing to create your custom, functional prototype or model using a CAD file ... which we can also custom design for your project.

Metal Forming

We use a press brake to bend sheet metal by lowering a punch onto sheet metal that has been positioned on top of a die. The metal may be

bent several times by a press brake until the desired form has been achieved.

Metal Punching

Sheet metal punching is a cutting process in which material is removed from a piece of sheet metal by applying a great enough shearing force. Punching

can be used to produce holes and cutouts of various shapes and sizes.

Finishing

Whether acrylic or metal, we use various machinery, hand-helds, etc., to sand, polish and trim your project to bring it to the final stage of

completion.